Now Reading: Uncover the True Root Cause of Manufacturing Downtime with AI

-

01

Uncover the True Root Cause of Manufacturing Downtime with AI

Uncover the True Root Cause of Manufacturing Downtime with AI

When manufacturing output drops by 15% in a quarter, the immediate reaction is often to blame a single machine or a single shift. But the 5 Whys Root Cause Analysis Tool from Visual Paradigm reveals that the real problem is rarely what it seems. This powerful, AI-powered software guides you through a structured, step-by-step process to dig past symptoms and find the fundamental issue that’s costing you time and money. It’s not just another diagramming app; it’s a professional-grade problem-solving engine designed for engineers, operations managers, and project leaders who need to stop the cycle of recurring issues. With a clean, intuitive interface and the ability to generate a complete analysis in seconds, this tool is the best-in-class solution for anyone who needs to solve complex problems quickly and effectively.

Unlike generic tools that offer a one-size-fits-all approach, Visual Paradigm’s 5 Whys Root Cause Analysis Tool is built specifically for this methodology. It provides a guided workflow that forces you to think critically, from defining the problem to creating a detailed action plan. The tool’s AI feature is a game-changer, allowing you to input a simple problem description and instantly receive a comprehensive analysis with potential solutions and an implementation roadmap. This dramatically accelerates the process, turning what could be a weeks-long investigation into a matter of hours. The result is a professional, printable report that serves as a single source of truth for your team, ensuring everyone is aligned on the root cause and the path forward.

Why the 5 Whys Method is the Gold Standard

The 5 Whys is a simple yet powerful technique for uncovering the root cause of a problem by asking “Why?” five times (or more, if needed). It’s a systematic way to peel back the layers of a problem, moving from the surface-level symptom to the underlying, fundamental cause. For example, if your production line is slow, the first “Why?” might be “Why did output drop?” The answer might be “Because the cycle time increased.” Then you ask, “Why did the cycle time increase?” The answer could be “Because there were more machine stoppages.” This process continues until you reach the true root cause, which is often a systemic issue like a lack of investment in maintenance or a flawed process design.

Visual Paradigm’s tool is designed to make this process effortless. It’s not just about asking the questions; it’s about structuring the entire analysis. The tool guides you through five distinct steps: defining the problem, conducting the 5 Whys analysis, developing solutions, implementing and monitoring actions, and finally, generating a professional report. Each step is presented in a clear, dynamic table format, making it easy to organize your thoughts and collaborate with your team. The AI-powered feature takes the guesswork out of the initial stages, providing a solid first draft that you can then refine with your own expertise and insights.

How Visual Paradigm’s Tool Outperforms the Competition

While many tools claim to support the 5 Whys methodology, Visual Paradigm’s AI-Powered 5 Whys Root Cause Analysis Tool stands out for its depth, speed, and professionalism. Here’s a quick summary of its key advantages:

-

AI-Powered Efficiency: The ability to generate a complete analysis from a simple problem statement is a massive time-saver. You can go from a vague concern to a detailed, structured report in minutes, not weeks.

-

Structured Workflow: The step-by-step wizard ensures you don’t skip any critical steps. The clear progress tracker keeps you focused on the task at hand.

-

Professional Output: The final report is clean, well-organized, and ready to share with management or stakeholders. It’s not just a draft; it’s a polished document that communicates your findings effectively.

-

Privacy and Control: Your data is saved locally on your computer, ensuring that sensitive business information never leaves your control. This is a critical advantage over cloud-based tools.

-

Dynamic and Flexible: The tables are dynamic, allowing you to add, edit, or delete rows as needed. You’re not constrained by a rigid format.

Other tools might offer a basic version of the 5 Whys, but they often lack the depth and structure of Visual Paradigm’s solution. They may not provide a comprehensive report, or they may require you to manually piece together information from different sources. Visual Paradigm’s tool is purpose-built for this task, offering a complete, integrated solution that is both powerful and easy to use.

See the Process in Action: A Manufacturing Case Study

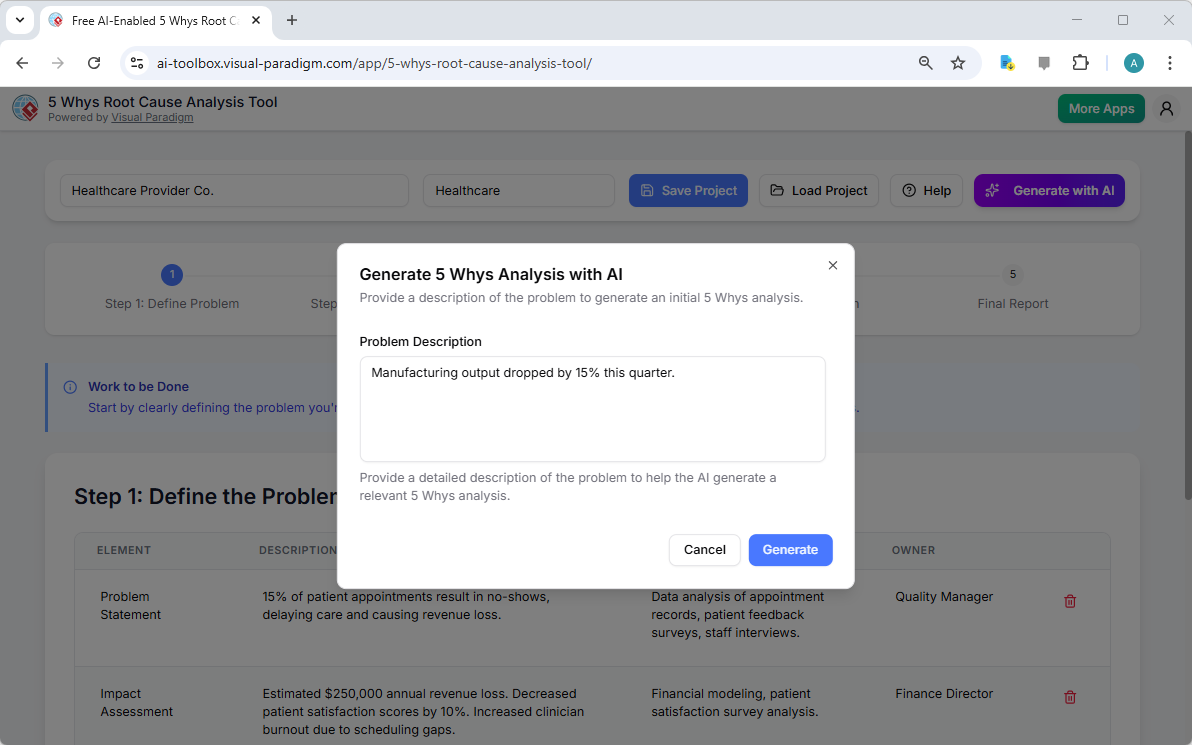

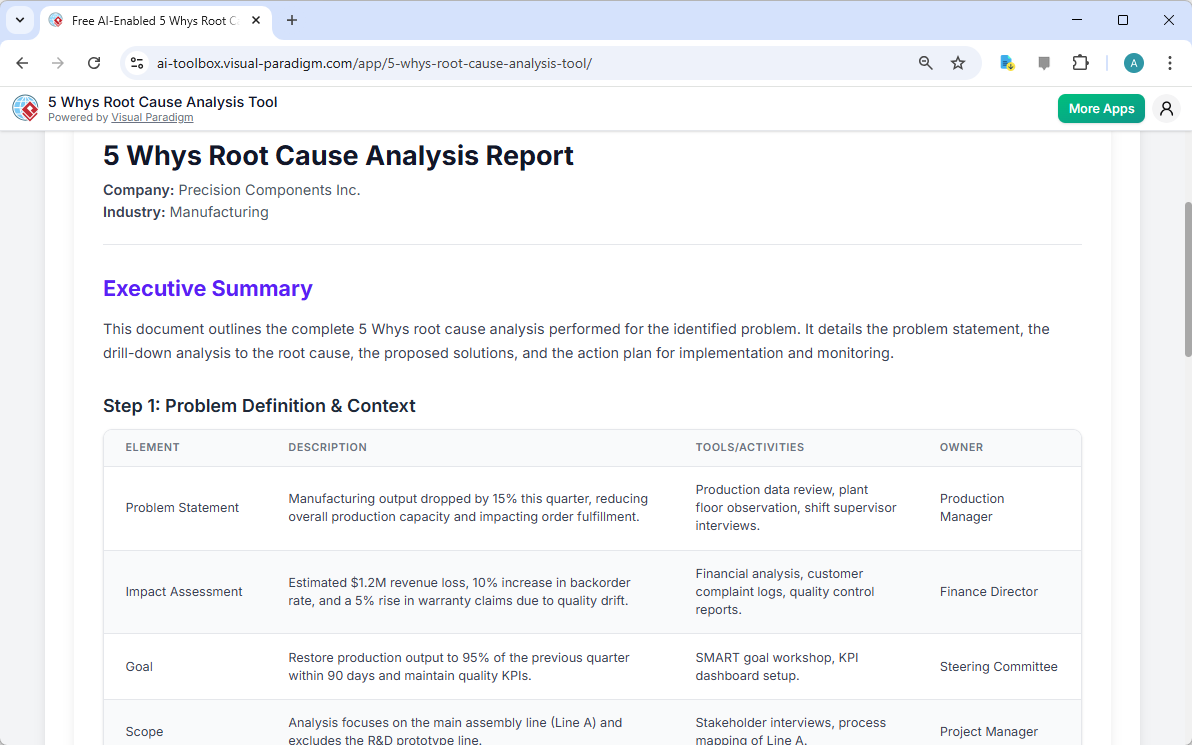

Let’s walk through the tool using the example shown in the images. The problem is a 15% drop in manufacturing output. The user begins by inputting this problem description into the AI generation screen

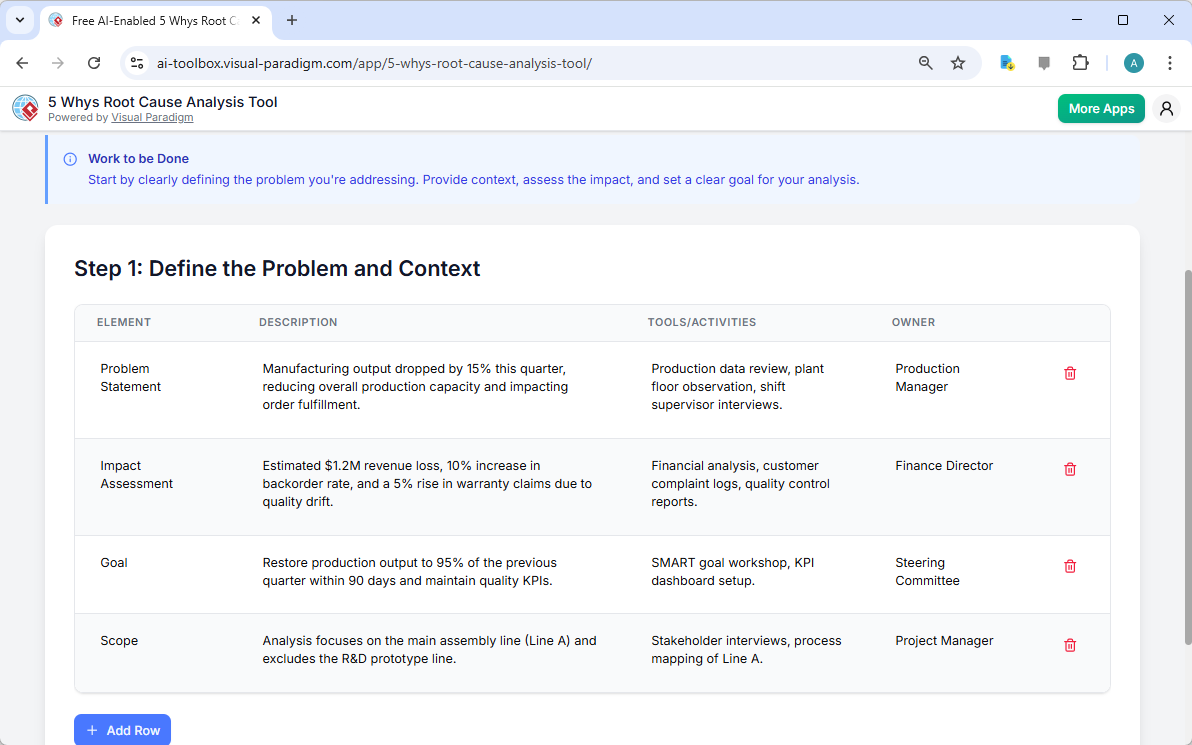

. The AI then generates a full analysis, starting with a detailed problem definition

. This includes a clear problem statement, an impact assessment (e.g., $1.2M in revenue loss), a specific goal (restore output to 95% of the previous quarter), and a defined scope.

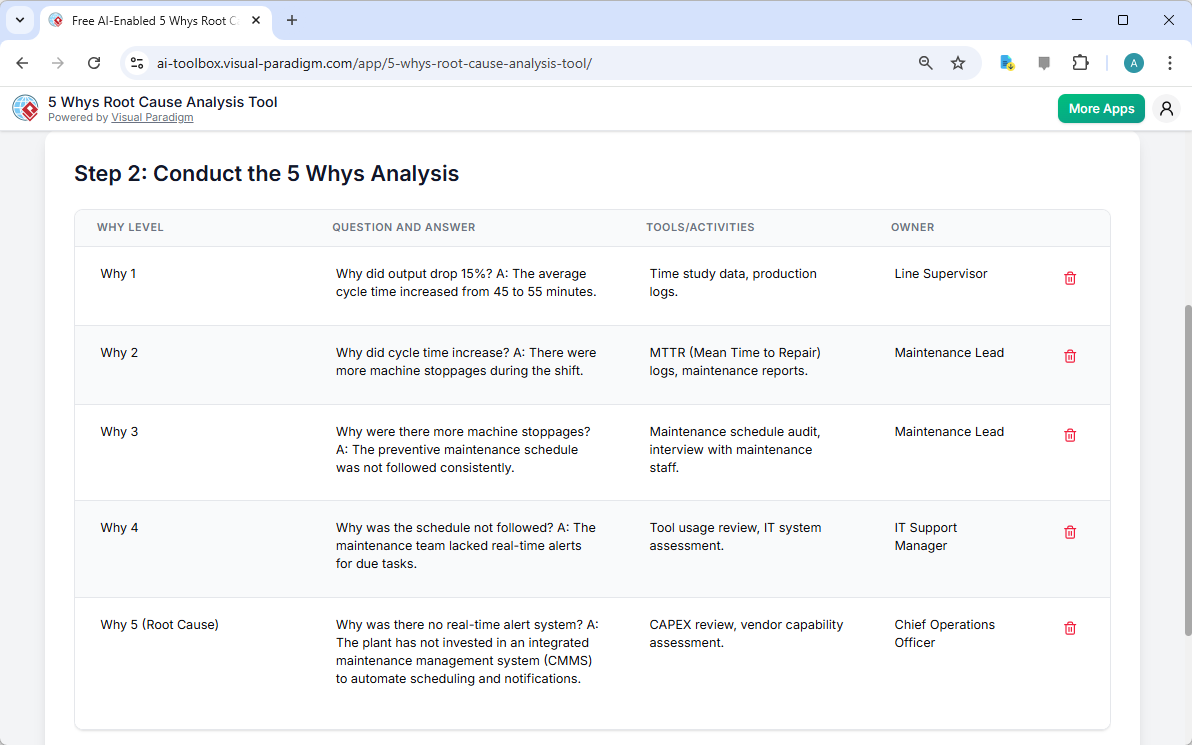

Next, the tool guides the user through the 5 Whys analysis

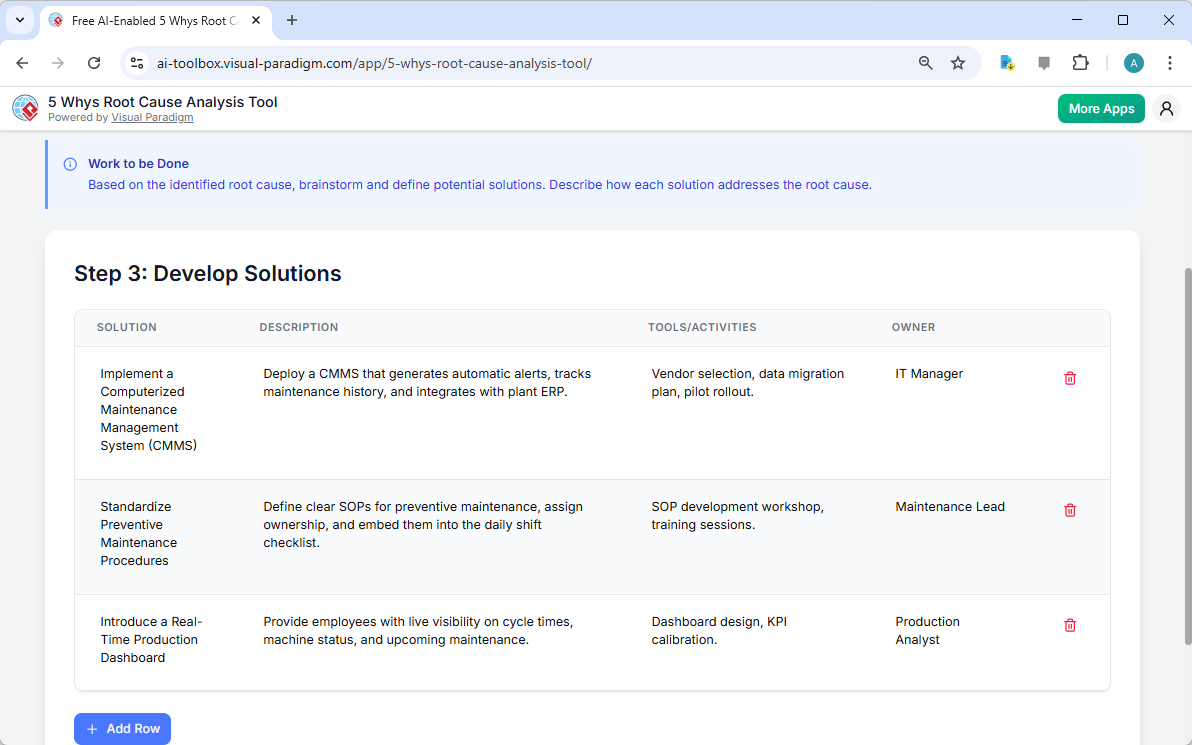

. The AI identifies the root cause: the plant has not invested in an integrated maintenance management system (CMMS). This is a critical insight that a less sophisticated tool might miss, as it would likely stop at the “machine stoppages” level. The tool then helps the user develop solutions

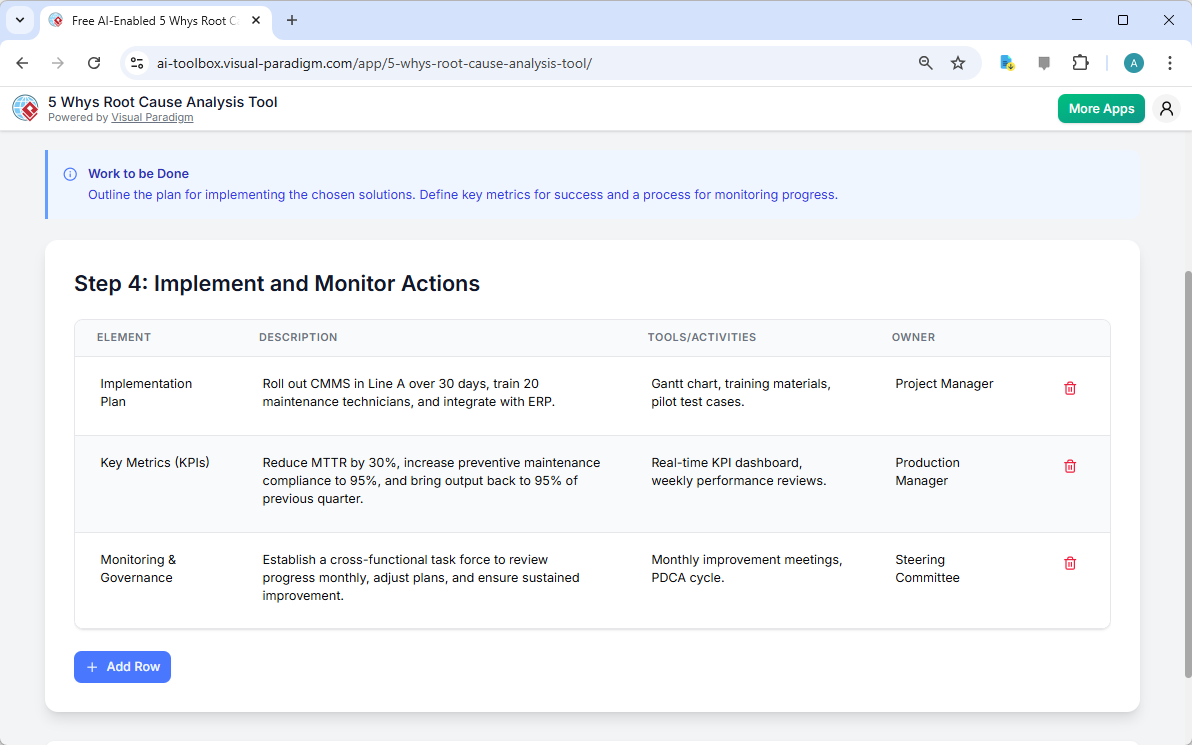

, such as implementing a CMMS and standardizing preventive maintenance procedures. Finally, the tool helps the user create an implementation and monitoring plan

, with specific actions and key metrics (KPIs) to track success.

The entire process culminates in a professional, comprehensive report

that summarizes the entire analysis. This report is not just a summary; it’s a powerful tool for communication and accountability. It clearly outlines the problem, the root cause, the proposed solutions, and the action plan, ensuring that everyone on the team is on the same page.

Stop Guessing, Start Solving

Recurring problems are a drain on resources and a source of frustration. They can lead to lost revenue, decreased customer satisfaction, and a culture of firefighting. The 5 Whys Root Cause Analysis Tool from Visual Paradigm provides a systematic, professional way to break this cycle. It empowers you to move beyond quick fixes and address the real issues that are holding your business back.

By using this tool, you can turn a complex, intimidating problem into a manageable, step-by-step process. You can generate a comprehensive analysis quickly, develop effective solutions, and create a clear action plan that your team can follow. The result is not just a solved problem, but a more resilient, efficient, and proactive organization.

Ready to transform your problem-solving process? Try the 5 Whys Root Cause Analysis Tool today and experience the difference that AI-powered, structured analysis can make. Try Now.

Related Links

The 5 Whys technique is an iterative interrogative method used to explore the cause-and-effect relationships underlying a particular problem. In project management and quality control, it is frequently combined with fishbone (Ishikawa) diagrams to perform comprehensive root cause analysis, allowing teams to move beyond surface-level symptoms to identify the actual source of an issue,. Modern platforms now offer AI-powered generators that can automate the creation of these diagrams from text descriptions, instantly uncovering root causes and organizing them into structured visual models,.

-

Fishbone Diagram and 5 Whys – Enhancing Root Cause Analysis: A specialized guide on integrating the 5 Whys technique with fishbone diagrams to improve problem-solving accuracy.

-

AI-Powered Fishbone Diagram Generator – Uncover Root Causes in Seconds: This tool leverages artificial intelligence to automate the identification of root causes and build structured diagrams instantly.

-

Unraveling Complex Issues: The Power of Cause and Effect Analysis: An article explaining how structured analysis enables teams to solve difficult business and operational problems.

-

Fishbone Analysis: Ishikawa Diagram Concepts and AI-Powered Tools: A detailed exploration of key analysis concepts and how generative AI enhances traditional root cause methodologies.

-

Free Online Fishbone Diagram Tool – Collaborative Problem Solving: A browser-based platform for creating professional diagrams to visually map cause-and-effect without software installation.

-

Practical Guide to Creating Cause and Effect Diagrams: A step-by-step tutorial for building effective diagrams to support systematic root cause analysis.

-

Cause and Effect Analysis Toolkit – Best Practices and Templates: A comprehensive resource providing templates and best practices for conducting in-depth problem analysis.

-

Step-by-Step Guide to Creating a Fishbone Diagram: A hands-on guide for identifying root causes within processes, projects, or complex systems.

-

Cause and Effect Diagram Gallery – Real-World Examples: A curated collection of diagrams showing how root causes are identified across engineering and quality management.

-

Fishbone (Ishikawa) Diagram Template – Ready-to-Use Resources: Access customizable templates to quickly visualize causal relationships and streamline the analysis process.